Frequently Asked Questions

What are the Semi-Flexible Panel Specifications?

- Warranty: 3 Year Comprehensive

- Panel size: 1050X540X3mm

- Panel Weight: 4 lbs

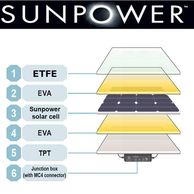

- Solar Cell Type: Monocrystalline Grade A

- Solar Cell Brand: SunPower USA

- Panel Array size: 32 Cells

- Cell Efficiency: 22-25%

- Maximum Current: 5.7A

- Panel Voltage: 17.8 Volts

- Maximum System Voltage: 1000V

- Waterproof Protection: IP67

- Life Expectancy: 90% output for 10 years and 80% output for 25 years

Series or Parallel? What is the best option for your system?

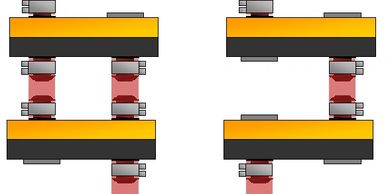

If your installation location is free from obstructions, then series is the preferred choice. On a series connection, the panel voltage is multiplied allowing long cable runs with minimal impact from voltage drops. The MPPT controller will convert that voltage into the optimum amperage required by your battery bank.

If your array is partially obstructed, a shadow on any portion of the array will adversely impact the entire array. In these situations, parallel connections will keep a portion of the array functioning when there is shading on one area. Your cable runs will be limited due to voltage drops.

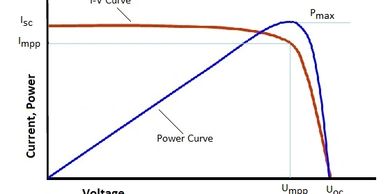

What is an I-V Curve Report?

What is an I-V Curve Report?

A current-voltage (I-V) curve shows the possible combinations of current and voltage output of a solar cell. A solar cell produces its maximum current when there is no resistance in the circuit. Each MSI Solar Panel is assigned a barcode, tested in the Lab, and results are made available to customers.

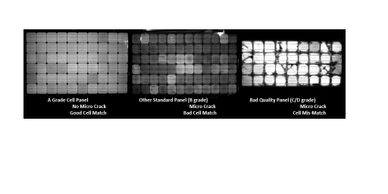

What is an EL Report?

PWM vs MPPT Charge Controllers?

What is an I-V Curve Report?

Electroluminscence image of a monocrystalline silicon wafer. The left image shows a panel manufactured with high quality cells. The center image shows a panel manufactured with improperly matched cells. Large variations in power are represented by the shading on the image. The right image shows a panel manufactured using Grade B, C, or D cells. These cells have micro cracks that significantly reduce the performance of the panel.

PWM vs MPPT Charge Controllers?

PWM vs MPPT Charge Controllers?

PWM vs MPPT Charge Controllers?

The PWM (Pulse Width Modulation) controller is a very basic device that interfaces a solar array to a battery bank. The voltage of the array will be lowered to match that of the battery bank reducing overall system performance.

The MPPT (Maximum Power Point Tracking) controller is more sophisticated in its functionality, it will adjust its input voltage to harvest the maximum power from the solar array and then transform this power to supply the varying voltage requirements of the battery bank. MPPT is by far the best choice for modern day solar arrays.

Will my solar charging system still work on cloudy days?

What is the difference between Monocrystalline and Polycrystalline solar panels?

What is the difference between Monocrystalline and Polycrystalline solar panels?

Absolutely! Solar panels achieve maximum output in direct sunlight, but they do work in normal daylight and cloudy weather also.

The system will generate less power on a cloudy day therefore we always recommend that you purchase the largest system possible within your installation space and budget. Larger systems will produce usable power regardless of the weather conditions.

What is the difference between Monocrystalline and Polycrystalline solar panels?

What is the difference between Monocrystalline and Polycrystalline solar panels?

What is the difference between Monocrystalline and Polycrystalline solar panels?

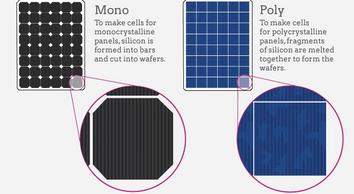

To make solar cells for monocrystalline solar panels, silicon is formed into bars and cut into wafers. These types of panels are called “monocrystalline” to indicate that the silicon used is single-crystal silicon. Because the cell is composed of a single crystal, the electrons that generate a flow of electricity have more room to move. As a result, monocrystalline panels are more efficient than their polycrystalline counterparts.

Polycrystalline solar panels are also made from silicon. However, instead of using a single crystal of silicon, manufacturers melt many fragments of silicon together to form the wafers for the panel. Polycrystalline solar panels are also referred to as “multi-crystalline,” or many-crystal silicon. Because there are many crystals in each cell, there is to less freedom for the electrons to move. As a result, polycrystalline solar panels have lower efficiency ratings than monocrystalline panels.

What size system do I need?

What is the difference between Monocrystalline and Polycrystalline solar panels?

What size system do I need?

The size of your system will depend on your power usage and requirements. Consider how many fridges you have on board, are you running AC loads through an inverter or do you regularly use high current devices such as a wash-down pump.

100W and 200W kits work well for light loads with single fridges and no AC inverter loads.

300W and 400W systems are recommended for multiple fridge / ice-maker applications or AC inverter loads.

Keep in mind that a larger system will generate more power on a cloudy day therefore we always recommend that you purchase the largest system possible within your installation space and budget.